Wire holding is a basic cycle in the development of high-voltage power modules, straightforwardly impacting the exhibition, unwavering quality, and life span of these imperative electronic parts. As power modules become progressively indispensable to state of the art applications — going from electric vehicles to environmentally friendly power frameworks — the nature of wire holding turns out to be perpetually significant. This article investigates the fundamental job of wire holding in high-voltage power modules, accentuating the critical advantages of cutting edge holding procedures, like ultrasonic welding, and the job of the wire bonder in guaranteeing superior execution, solid associations.

Why Wire Holding Matters in High-Voltage Power Modules

High-voltage power modules are fundamental for controlling and changing over electrical energy in various requesting applications. These modules should endure high flows, high voltages, and outrageous ecological circumstances, all while keeping up with electrical and mechanical dependability. Wire holding assumes a vital part in guaranteeing that the associations inside these modules meet these tough prerequisites.

1. Electrical Conductivity and Effectiveness

In power hardware, especially in high-voltage applications, the productivity of the framework is exceptionally reliant upon the nature of the electrical associations. Clumsy wire bonds can present electrical opposition, prompting power misfortunes, warming, and diminished by and large framework proficiency. This is particularly basic in high-voltage power modules, where even minor misfortunes can affect execution.

2. Warm Administration

High-voltage power modules produce critical intensity during activity, and warm administration is a vital worry in their plan and usefulness. Extreme intensity can debase parts, decrease proficiency, and lead to disappointment. Wire securities themselves should have the option to deal with the intensity produced by the electrical flow while guaranteeing that the intensity is dispersed really across the module.

3. Mechanical Strength and Toughness

High-voltage power modules frequently work in conditions where they are dependent upon mechanical pressure, like vibrations, shocks, and warm cycling. The wire bonds should have the option to endure these burdens without breaking or debasing over the long haul. Mechanical disappointment of a wire bond can bring about the deficiency of electrical network, prompting framework breakdowns or complete disappointment.

4. Long haul Dependability and Natural Obstruction

High-voltage power modules are commonly utilized in brutal conditions where they might be presented to temperature limits, stickiness, and, surprisingly, destructive substances. To guarantee the life span of the module, the wire bonds should be impervious to ecological debasement. After some time, factors like erosion, oxidation, or warm cycling can debilitate low quality bonds, prompting disappointments.

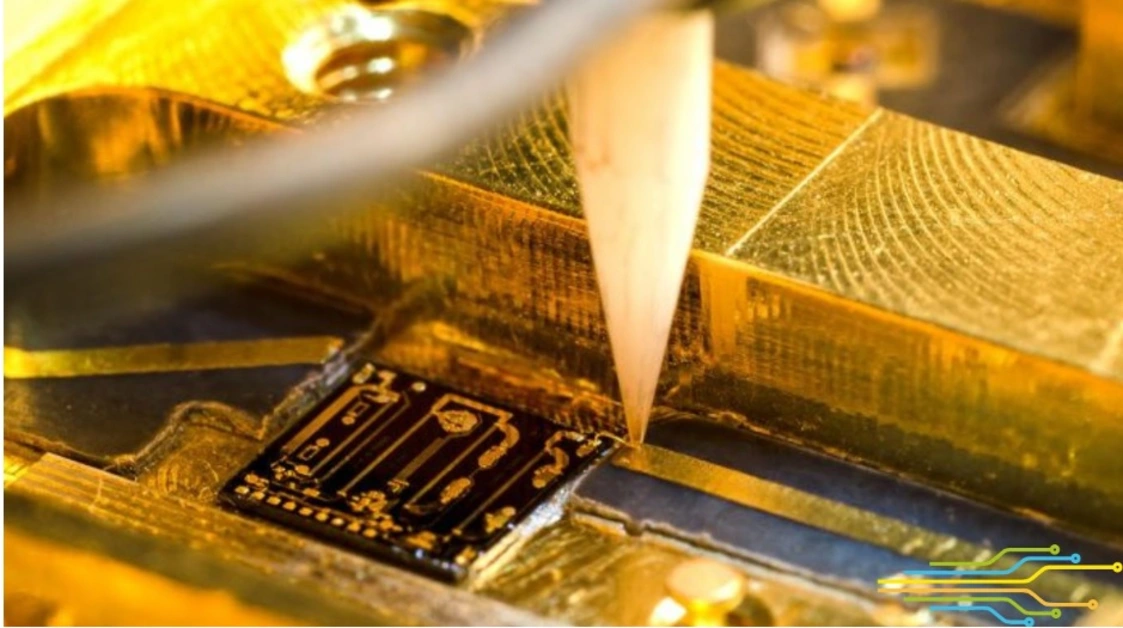

Ultrasonic Welding: An Accuracy Holding Method

Ultrasonic welding is a high-accuracy method utilized in wire holding that is especially valuable in high-voltage power modules. This technique utilizes high-recurrence sound waves to create restricted heat at the connection point between the wire and the holding surface. The intensity makes the metal mellow and shape areas of strength for a, bond.

For high-voltage power modules, ultrasonic welding offers a few advantages:

Diminished warm effect: On the grounds that ultrasonic welding creates heat just at the bond interface, it limits the gamble of harming touchy parts in the module.

High bond strength: The interaction makes solid mechanical and electrical bonds that are fundamental for the module’s unwavering quality.

Consistency: Ultrasonic welding produces exceptionally reliable outcomes, guaranteeing that each wire bond fulfills severe quality guidelines.

End

Wire holding is an essential cycle in the assembling of high-voltage power modules, assuming an imperative part in guaranteeing that these parts can deal with the electrical, warm, and mechanical burdens they are exposed to. The utilization of cutting edge wire holding methods, especially ultrasonic welding, is basic in accomplishing the elite presentation, dependability, and sturdiness expected in current power gadgets.

For more information,click here.