Introduction to Swing Arm Mechanics

The physics of a swing arm have long interested scientists, designers, and creators. Swing arms have become a standard component in many different fields, from manufacturing to robotics, thanks to their adaptability and sleek design. But the question remains, how did this extraordinary system develop? Where does the magic happen? And where do you see swing arm technology going from here?

In this article, we will dig into the interesting realm of swing arm mechanics, discussing its origins, development, uses, benefits, drawbacks, and potential for future advancements. Prepare to fasten your seatbelts and spring into action as we explore the intricacies of this fascinating creation.

History and Evolution of Swing Arms

Swing arms have a rich history that spans back centuries. Ancient cultures employed the notion of a swinging arm mechanism for a wide range of purposes, from water wells to catapults.

The trebuchet, a medieval siege weapon, is sometimes cited as the oldest example of swing arm mechanics. This enormous machine has a huge swinging arm that launched missiles with tremendous power. Its clever construction gave it superior precision and force over contemporary weapons.

Swing arms became commonplace in household objects like clocks and lights as technology progressed. Clocks with pendulums, which used swing arms to control the movement and preserve correct time, first appeared in the 18th century.

Swing arm mechanisms were commonly utilized in machines throughout the Industrial Revolution, including steam engines and presses. The efficiency of these machines was dependent on the smooth motions provided by their swing arms.

Swing arm technology has advanced with the emergence of cutting-edge technical methods. They are now used in several fields, from the car industry and robotics to aerospace engineering and prosthetics.

Engineers have been able to design swing arms that are stronger and lighter than ever before because to the development of materials like lightweight alloys and sophisticated composites.

There is no limit to the ways in which swing arm technology can improve in the future. The efficiency and creativity of this mechanical marvel are only going to increase as our knowledge of physics grows and as novel materials are created.

How Do Swing Arms Work?

Swing arms, which function on the principles of pivoting and rotation, are intriguing mechanical devices. A rigid bar or arm is attached to a stationary point (the pivot or fulcrum) in these devices. The swing arm has a lot of freedom of movement since it can swing back and forth and rotate on its pivot.

Swing arms are based on a straightforward yet innovative mechanism. One end of the arm responds to a push or pull by moving in the opposite direction. The arm is able to move because of the way its anatomy and design produce leverage.

Picture yourself pressing down on the handle of a seesaw at the playground to get a feel for how swing arms function. When you push down on one end, the other one will rise. Because of the torque your force produces around the pivot point, the object begins to rotate.

Swing arms are another example of this principle in use, but in a wider variety of configurations. For smooth motion and accurate adjustment, certain swing arms are powered by hydraulic systems or electric motors.

Swing arms provide for movability and customization, whether they’re a part of heavy machinery or a desk light. Without the need for intricate mechanics or finicky adjustments, users may place things with pinpoint accuracy.

Forces are leveraged around a central pivot point to accomplish the work of a swing arm. Their ingenious construction makes it possible to move and place them with ease for a wide range of uses in many different fields.

Applications of Swing Arm Mechanisms

The flexibility and dependability of swing arm mechanics have led to their widespread use. One significant use is in the realm of robotics. Precision and efficiency in movement are two reasons why robotic arms frequently employ swing arms. Swing arm mechanisms are vital in increasing efficiency and precision in both production lines and operating rooms.

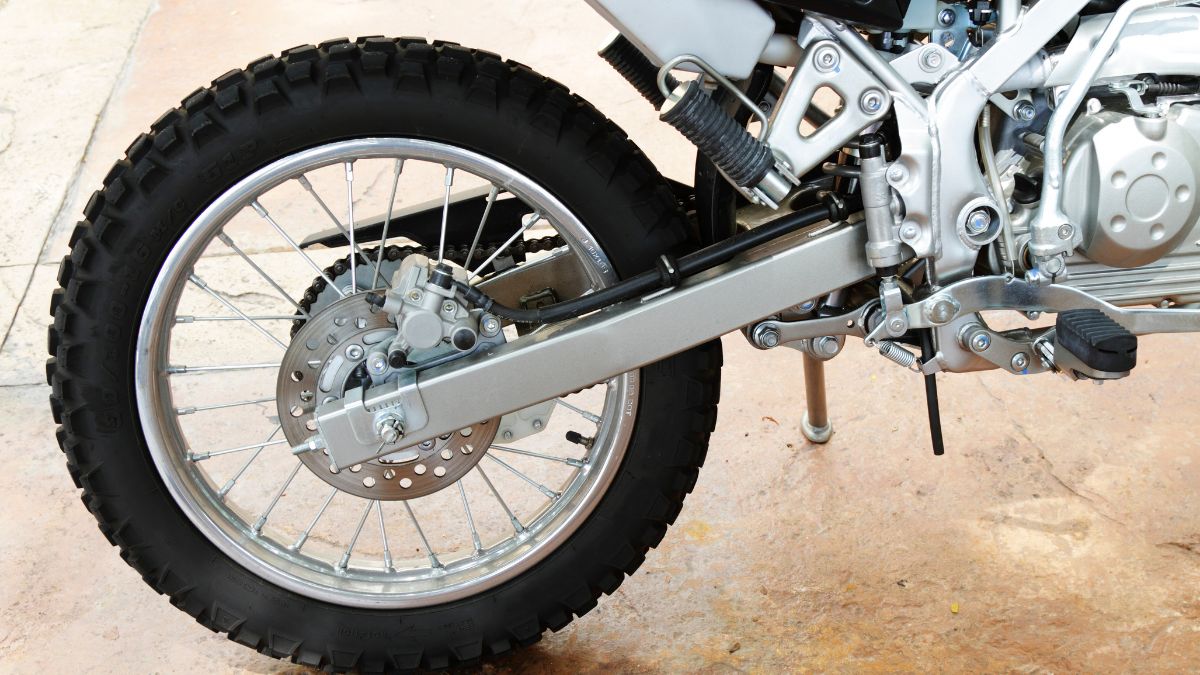

The vehicle industry is yet another successful application of swing arm mechanics. Swing arms are a common component of automobile suspensions because of the benefits they provide to vehicle handling and ride comfort.

The entertainment business has also benefited from swing arm technology. These innovative tools allow for engaging sights that keep spectators enthralled, and can be seen anywhere from amusement park rides that replicate exhilarating experiences to camera cranes used for dynamic views in movies.

The healthcare sector has incorporated swing arm mechanics as well. Swing arms are commonly seen on medical equipment like examination lamps and IV poles to allow for flexible placement choices for healthcare providers.

Swing arms are also utilized in the building industry. These mechanics are what allow retractable awnings to extend and retract with minimum effort, making them ideal for use on hot days.

More and more creative uses of swing arm mechanics in other fields are to be anticipated as technology develops. There appears to be no limit to the number of industries that this adaptable mechanism may transform, from aeronautical engineering to home automation systems.

Swing arm mechanisms have a wide variety of uses and have had a significant influence on many different industries because of their innovative design.

Advantages and Disadvantages of Swing Arms

The versatile and innovative design of swing arms provides a number of benefits in many contexts. Swing arms are very adaptable. They have many potential applications, from the car industry to robotics to even household goods. Because of this malleability, they may easily accommodate a wide variety of circumstances.

Swing arms also have the benefit of being able to move precisely and with great precision. Because of how the mechanics are constructed, travel along the predetermined route is effortless and precise. When performing repetitive motions or needing to place things precisely, this level of accuracy is essential.

Swing arms are often lauded for their diminutive size. Because of their modest size, they are perfect for situations when space is at a premium or when a low profile is preferred. This quality also allows for smooth incorporation into preexisting frameworks with minimal effort.

However, swing arms have their own limitations just like any other mechanical device. Constant motion and tension on the joints can lead to wear and tear over time, which is a drawback. To keep things running smoothly and reliably for as long as possible, routine maintenance may be necessary.

Swing arm systems also have the disadvantage of not always being easy to design for particular uses. During the design process, it is crucial to think about things like how the weight will be distributed, how much torque will be needed, and how far the joint will be able to move.

Future Innovations in Swing Arm Technology

It is not surprising that swing arm systems are developing as technology advances. The capabilities of these innovative tools are always being expanded upon by engineers and designers. Some fascinating developments in swing arm technology are on the horizon.

Smart Swing Arms: With the growth of smart home technology, it’s just a matter of time until swing arms become smarter too. Think of a swing arm that is connected to your phone or voice assistant via sensors. You may move it around from a distance, position it as you like, or even set it to operate autonomously according to your instructions.

Swing arm weight is one area that can benefit from using lighter materials. Strong yet hefty materials like steel or aluminum are typically used in today’s designs. More effective and nimble swing arms may be possible in the future because to developments in lightweight materials like carbon fiber composites or graphene.

Swing arms will move more precisely and smoothly as our understanding of precision engineering grows. Artificial intelligence (AI) algorithms that determine ideal trajectories and reduce vibrations during operation may be a key component of future developments involving sophisticated robotic systems.

Future developments may include multi-axis motion capabilities, allowing swing arm systems to move in more than just one plane of motion. Applications like industrial automation and surgical robots might benefit greatly from this, since it would allow for more complicated movements and greater flexibility.

The wearable robotic gadgets’ meticulously built swinging mechanics might help those with mobility problems gain more strength and range of motion.The development of new swing arms is really fascinating.

Conclusion

Swing arm mechanics have transformed different sectors and applications, showing the genius of human design and engineering. Swing arms have gone a long way from their primitive origins in ancient cultures to the cutting-edge technologies of today. Swing arms have been used for anything from basic tools to large machines throughout history. Manufacturing, robotics, the automobile industry, the aerospace industry, and even the entertainment industry may all benefit from their use.

The capacity to rotate around a fixed point offers superior accuracy and adaptability compared to other technologies. Swing arm systems provide several benefits that can’t be ignored. They provide for more freedom of movement, more agility, greater efficiency in repeated operations, and simpler operation. Additionally, their small shape makes them suited for applications with space restrictions.

The drawbacks, however, must not be overlooked. Depending on how they’re built, swing arms may have restricted mobility or strength. The need for repairs over time is another factor that must be carefully considered.

swing arm mechanics are vital in many modern fields due to its brilliant design and wide range of potential applications. Swing arm mechanisms are incredible mechanical marvels, but as we continue to push limits and discover new possibilities in engineering and technology, it’s safe to assume there will always be potential for improvement.