Photoelectric sensors have become essential tools in industrial automation and other fields, transforming our perception and interaction with the environment. Fundamentally, these clever gadgets use light to detect whether items are present or absent, opening up a wide range of uses in various sectors of the economy.

The discovery of the photoelectric effect in the early 20th century provided the impetus for creating the first light-sensitive detectors, where photoelectric sensing started. The development of photoelectric sensors has been driven by developments in electronics, optics, and materials research, resulting in the complex and multifunctional gadgets we use daily.

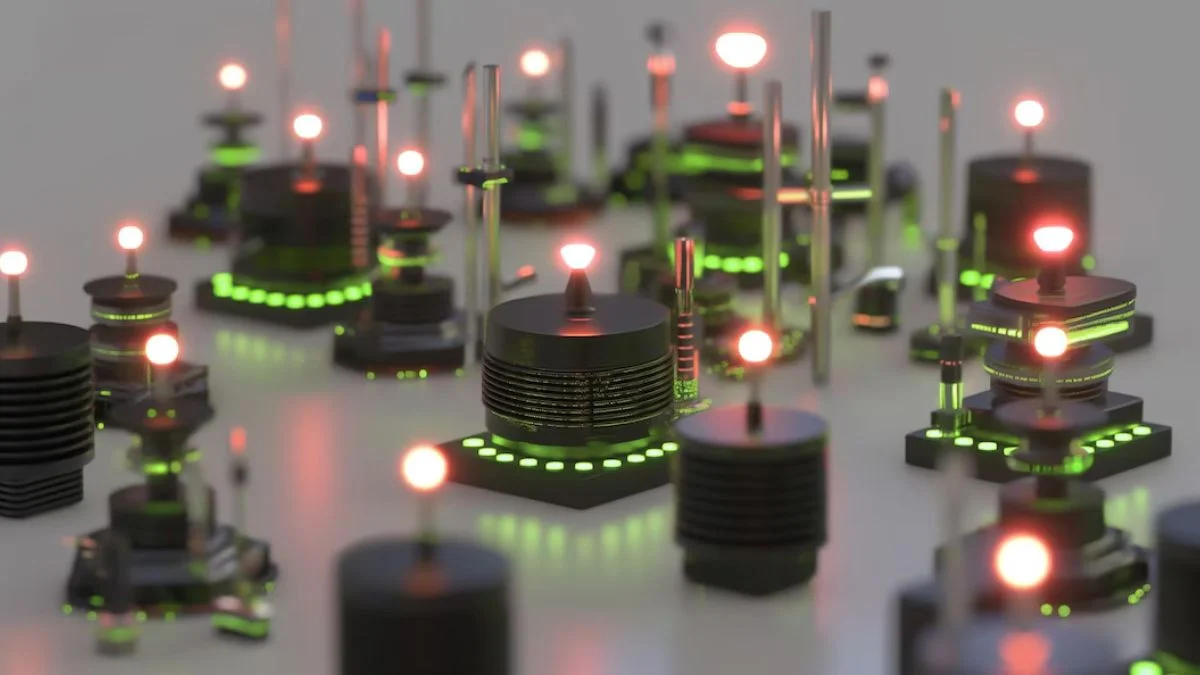

Since its founding in 1945, Pepperl+Fuchs has been at the forefront of innovative photoelectric sensor technology, making it a pioneer in this industry. The company’s steadfast dedication to innovation, quality, and dependability has led to the development of a wide range of photoelectric sensors suitable for several uses. Pepperl+Fuchs provides solutions that enable companies to run more effectively, safely, and productively. These solutions range from small sensors that are effortlessly incorporated into compact devices to sturdy industrial sensors made to survive harsh conditions.

The significance of photoelectric sensors in today’s industrial environment cannot be emphasized. They are perfect for various applications, such as item detection, position sensing, counting, and presence verification, because of their non-contact sensing abilities, great precision, quick response times, and immunity to electromagnetic interference. Their ability to adapt to different object kinds, sensor ranges, and environmental circumstances further solidifies their position as important parts of automation systems worldwide.

Photoelectric sensors are widely used in manufacturing, automobile assembly lines, packing, and logistics centers. They are essential for optimizing workflows, increasing output, and guaranteeing the security of workers and assets.

Photoelectric Sensor Fundamentals

Photoelectric Working Principle

A straightforward but effective principle—converting light energy into an electrical signal—lays the foundation of all photoelectric sensors. The process by which photons of light impact photosensitive substance-free electrons and generate a quantifiable current is known as the photoelectric effect.

A light source, frequently an LED, emits a light beam in a standard photoelectric sensor. The amount of light that reaches the receiver changes when an object enters the sensing field because it disrupts or reflects this beam. A photodetector detects this change in light intensity and transforms it into an electrical output. After that, the sensor’s electronics process the signal to initiate an output, like turning on a relay or delivering a digital signal to a control system.

Key Components of a Photoelectric Sensor and Their Functions

- Emitter: Generates the light beam, typically using an LED due to its efficiency, long lifespan, and compact size.

- Receiver: Detects the light beam, converting it into an electrical signal. Common types include photodiodes and phototransistors.

- Amplifier and Signal Processing: Amplifies the weak electrical signal from the receiver and processes it to generate a usable output.

- Output Stage: Provides the sensor’s output signal, a discrete switching signal (e.g., PNP or NPN), or an analog signal proportional to the received light intensity.

- Optics: Lenses and reflectors shape and focus the light beam, optimizing the sensor’s performance for specific applications.

- Housing: Protects the sensor’s internal components from environmental factors and provides mounting options.

Types of Photoelectric Sensors

Photoelectric sensors are categorized based on their sensing method, each offering distinct advantages and trade-offs for different applications:

- Through-Beam Sensors: Emitter and receiver are housed in separate units. Object detection occurs when the beam is interrupted, offering high accuracy and long sensing distances. It is ideal for applications where precise detection is crucial but requires careful alignment.

- Retroreflective Sensors: The emitter and receiver are housed in the same unit, with a reflector opposite them. Object detection occurs when the beam is reflected to the receiver. Easy to install and align but sensitive to highly reflective objects and environmental contaminants.

- Diffuse Sensors: Emitter and receiver are housed in the same unit. Object detection occurs when the beam is reflected from the object’s surface to the receiver. It is versatile and suitable for various object types, but sensing distance is limited compared to through-beam sensors.

Advantages and disadvantages of photoelectric sensors

Photoelectric sensors offer many advantages, making them indispensable in industrial and automation applications. However, like any technology, they also have certain limitations to consider during selection and implementation.

Advantages

- Non-Contact Sensing: Prevents wear and tear on both sensor and target, ideal for delicate materials.

- High Accuracy & Reliability: Delivers consistent, dependable performance even in challenging settings.

- Fast Response Time: Detects rapid changes, perfect for high-speed applications like conveyor monitoring.

- Wide Sensing Range: Available in various ranges, accommodating diverse applications and object sizes.

- Immunity to EMI: Ensures reliable operation in electrically noisy environments.

- Versatility: Adaptable to a wide array of industrial and automation applications.

Disadvantages

- Environmental Sensitivity: Dust, dirt, and ambient light can impact performance, necessitating careful sensor selection and placement.

- Limited range (vs. other types): While offering a good range, other technologies like ultrasonic may reach further, which is important to consider for specific needs.

- Misalignment Risk: Proper alignment, especially in through-beam and retroreflective setups, is crucial to avoid reduced sensitivity or detection failure.

- In essence, photoelectric sensors are powerful tools, but their successful implementation demands understanding their strengths and weaknesses to harness their full potential in automation.

Photoelectric Sensor Applications

The versatility of photoelectric sensors shines through their extensive application across many established and emerging industries.

Industrial Applications

Manufacturing And Automation:

- Object Counting & Sorting: Precisely track and categorize items on production lines, optimizing efficiency.

- Presence Detection & Position Sensing: Verify object existence and location, which is critical for automated processes.

- Conveyor Belt Control & Material Handling: Manage conveyor operations and ensure seamless material flow.

- Packaging & Labeling: Guarantee accurate product packaging and labeling for consumer safety and regulatory compliance.

- Safety & Security Systems: Detects intrusions, safeguarding personnel and assets.

Automotive Industry:

- Vehicle Assembly & Quality Control: Ensure precise component placement and adherence to quality standards.

- Door & Window Control: Automate door and window operations, enhancing convenience and accessibility.

- Parking Assistance & Collision Avoidance: Enhance driver awareness and prevent accidents.

Food And Beverage Industry:

- Packaging & Bottling Lines: Monitor container presence and fill levels, minimizing waste and ensuring product integrity.

- Contamination Detection & Quality Control: Identify foreign objects and defects, safeguarding consumer health.

- Level Sensing & Process Control: Manage liquid and bulk material levels, optimizing production processes.

Other Industries

- Pharmaceutical & Medical Devices: Ensure sterile environments and verify proper equipment operation.

- Printing & Paper Industry: Control paper feed and detect jams, maintaining production efficiency.

- Robotics & Drones: Enable navigation, obstacle avoidance, and object recognition.

Emerging Applications

Beyond traditional industrial settings, photoelectric sensors are finding their way into new and exciting applications:

- Smart Homes & Building Automation: Control lighting, HVAC systems, and security features based on occupancy and environmental conditions.

- Agriculture & Environmental Monitoring: Monitor soil moisture, crop health, and water levels, promoting sustainable practices.

- Healthcare & Assistive Technologies: Facilitate patient monitoring, mobility assistance, and smart prosthetics.

The continuous evolution of photoelectric sensor technology and adaptability ensures their continued relevance and expansion into new frontiers. As we embrace the future, these sensors will undoubtedly play an even more significant role in shaping the world around us, driving innovation, and improving our quality of life.

Selection And Installation Considerations

Choosing and implementing the right photoelectric sensor involves carefully considering several factors to ensure optimal performance and longevity.

Factors to consider when choosing a photoelectric sensor

- Sensing Range & Object Characteristics: The size, shape, color, and reflectivity of the target object influence the choice of sensor type and sensing range. Consider the maximum distance the sensor must detect and the object’s properties.

- Environmental Conditions: Ambient light, dust, dirt, humidity, and temperature can affect sensor performance. Select sensors with appropriate environmental ratings and consider protective measures if necessary.

- Output Type & Interface Requirements: Choose the appropriate output type (e.g., PNP, NPN, analog) and communication interface (e.g., discrete, IO-Link) to integrate the sensor into your control system seamlessly.

Installation best practices

- Mounting & Alignment: Ensure proper mounting and alignment, especially for through-beam and retroreflective sensors, to maximize detection accuracy and minimize false triggering.

- Wiring & Connection: Follow manufacturer recommendations for wiring and connection to avoid signal interference and ensure reliable operation.

- Troubleshooting & Maintenance: Implement a preventive maintenance schedule to inspect sensor functionality, clean lenses and reflectors, and address any issues promptly.

Careful planning and attention to detail during selection and installation will ensure that your photoelectric sensors operate reliably and contribute to the efficiency and safety of your automation system.

Photoelectric sensors have firmly established themselves as indispensable components in modern industry and beyond. Their evolution from basic light detectors to sophisticated sensing solutions showcases the remarkable technological progress. With their precision, reliability, and adaptability, these sensors continue to drive advancements in automation, safety, and efficiency across diverse sectors. As technology continues its rapid march forward, we can anticipate even greater integration and innovation in the field of photoelectric sensing, shaping a future where these devices play an even more pivotal role in our interconnected world.

For more information click here.