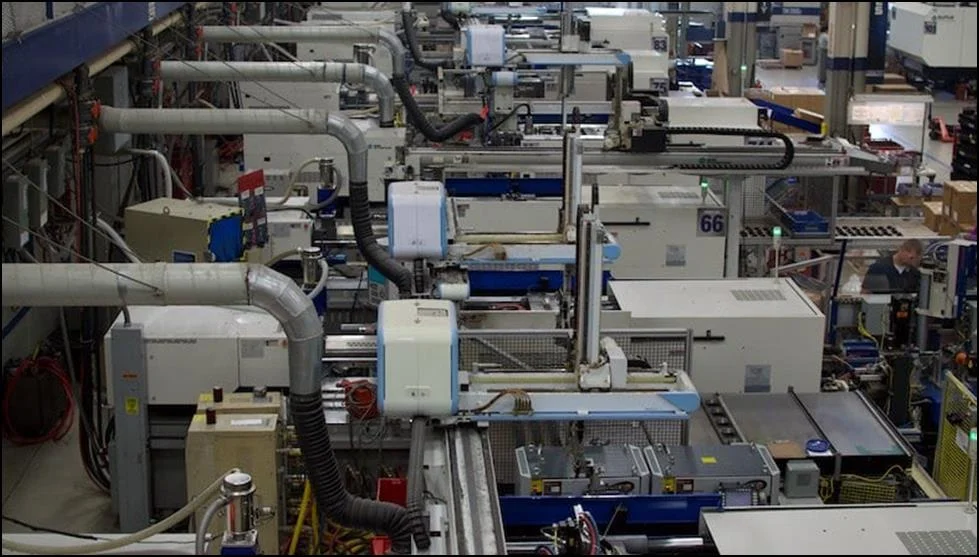

Unveil the future of manufacturing with high-speed injection molding. This technique promises efficiency and precision in tech production!

How High-Speed Injection Molding Works?

Mechanics

The kit which is responsible for the molten polymer charge includes a fast rotating screw and a piston that takes an alternate path. A liquid metal casting is then pumped with the help of a hydraulic system which runs at very high speed into the mold cavity through a multi point-injection process. Geometric accuracy and tight tolerances as well as control movement will duplicate the design of the mold making.

Pressure

In High Speed Injection Molding the plastic melt is subjected to outstanding force which is sufficient to fill the mold cavity. So, the pressure is a must, and length of the pressure will be from some thousands to tens of thousands of pounds per square inch, because the whole results will keep the intricate details filled and prevent defects like voids or sink marks.

Temperature

Temperature control in the course of high-speed injection-molding is accurate down to the smallest detail. In the extruder, the small plastic pieces with determined weight are heated until the melting point, which then are condensed through the injection alignment and formed into the shape of the final intended product. The temperature control of the liquefied material ensures the maintained flow and viscosity of flow, essential for the production of high-quality and robust parts.

Speed

What makes High-Speed Injection Molding stand out is its fast moving speed, ranging between 200mm/s and 2000mm/s. High speed injection and mold filling that can lead to shorter cycle time imply that it is gained with no defects and also not with dimensional inaccuracy raised.

Process

High-Speed Injection Molding comprises two main steps: the first, the fixing and closing of the mold and clamp, and second, the injection and setting of the material. The injection unit continues to move forwards, while the plastic is getting melted and injected into the mold cavity. Following a brief return time where the part cools and solidifies, the part is ejected from the mold, ready for further processing or assembly.

Key Components of High-Speed Injection Molding Machines!

Machinery

This High-Speed Injection Molding technology has the ability to utilize rugged equipment and sophisticated control structures. Through meticulously created elements such as the barrel, screw and hydraulic system, these rifles give the guarantee that they perform ideally and persist in severe conditions.

Clamping Unit

The clamping unit of the High-Speed Injection Molding machine is characterized as the part with the biggest force to hold the mold closed during the injection. It forms a framework of solid platens, tie bars, and a hydraulic system whose hydraulic system has a powerful pump to perform the action for high speed work.

Injection Unit

The efficient molding machines of injection speed are installed with the advanced unit that has high torque motors and accurate control system. The moveable screw is the one which triggers off the heat and forces the plastic through the mold cavity with high speed and accurate pressure thus leading to a desired molded object.

Mold System

High-Speed Injection Molding Machinery with intricate systems of molds implements rapid tool change and efficient cooling directed towards the same goal. Specification of matching hot runners, quick-release mechanisms and thermal control elements prevents mold fouling and reduces processing cycle time.

Automation

Automated High Production systems contain advanced automation solutions which are designed to simplify the cycle of the production process and achieve high-efficiency results. Multiple input, machining to mold changing, and part ejection are done with minimum human intervention which result in improved productivity, therefore, faster operation, and lowdown time.

Robotics

The robotics implements in the High-Speed Injection Molding field are designed to carry out tasks of part removal, inspection and packaging with pace and precision. Cooperative robots, including the ones with end effectors, for example, vision systems and adaptive grippers, provide flexibility and versatility to the manufacturing processes.

| Key Components | Machinery | Clamping Unit | Injection Unit | Mold System | Automation | Robotics |

| Function | Drives the entire molding process | Secures mold during injection | Injects molten plastic into mold | Holds and cools the injected plastic | Streamlines production steps | Handles parts and assists operations |

| Core Elements | Motors, gears, PLCs | Toggle or hydraulic system | Screw & barrel, nozzle | Cavities, cores, cooling channels | Sensors, software | Grippers, arms, controllers |

| Speed (Cycles/Min) | Varies with model | Up to 1000 mm/s closing speed | Up to 500 mm/s injection speed | – | Real-time monitoring | Up to 150 cycles/hr |

| Pressure Handling | – | Up to 3000 tons clamping force | Up to 2000 bar injection pressure | – | Adjusts parameters for optimal performance | – |

| Accuracy & Precision | High control over process parameters | Precision mold alignment | Precise control of injection volume | Tight tolerance holding | Reduces human error | High repeatability in placement |

| Materials Used | Steel, aluminum for components | High-grade steel for platens | Heat-resistant metals for screw and barrel | Tool steel, aluminum for molds | – | Durable materials for longevity |

| Innovation & Trends | Smart machines with IoT integration | Electric clamping for energy efficiency | AI for dynamic pressure adjustment | 3D-printed molds for rapid prototyping | Industry 4.0 integration | Collaborative robots (coots) for safety |

Benefits of High-Speed Injection Molding in Tech Manufacturing!

Productivity

The High-Speed Injection Molding is a good investment because it is able to increase productivity in tech manufacturing by decreasing the cycle time and doing more in a certain time period. The fast molding process in tandem with quick mold changing enables manufacturers to produce multiple parts in a short time, satisfying consumer requirements and retaining the customers’ lead over competitors.

Precision

The Fast injection molding reaches the level of great process accuracy during parts production delivering the high tolerance and intricate geometry to very precise details. Actuated by highly precise optics, accurate injection and mold filling are accomplished with high-speed movements. This is what makes the resulting parts dimensions as consistent as possible with minimal variability.

Sustainability

High-Speed Injection Molding is helping to take the manufacturing of tech to a higher level by minimizing the material waste and hence promoting sustainability.

High-speed cycle times and processes that minimize energy use per component contribute to a lower general energy consumption and, consequently, lower emission concentration in the environment. In particular, long-lasting and resistant parts are very helpful in extending the life of the product and less strain on the environment.

Challenges and Solutions in High-Speed Injection Molding!

Material Behavior

The High-Speed Injection Molding operations are constrained by the dynamics of material behavior such as alterations of viscosity, and thermal depletion at speeds of injection. Solving such melt and injection issues may involve `check` optimizing melt temperature and `check` adjusting injection parameters, as well as `check` using additives to facilitate the flow and stability, all achieving the same quality assurance for various parts.

Mold Durability

High-Speed Injection Molding surpasses standard tolerance since it causes strain to the mold due to speed and high pressure, creating wear and fatigue. For instance, sensors can be introduced in the structure of the molds, routine maintenance is introduced and temperature control is ensured to achieve the specified mold durability and productivity.

Speed vs. Accuracy

High-Speed Injection Molding can likewise direly need for speed and precision, as rapid ones might impact part quality. Solutions include perfecting machine settings, considering injection speed and pressure, and using advanced control systems that can enable a quick operation while maintaining high-quality molding characteristics.

Optimizing the High-Speed Injection Molding Process!

Material Selection

The key when it comes to high-speed injection molding involves selecting the most suitable material. ABS, PET, and PET are top considerations since they have good ductility and withstand well. To flip the molecules and avoid warping and warping, try considering MFIs and thermal stability. Directly from material prep, as articulated by drying and moisture level, also influences the performance.

Mold Design

For a proper, fast molding of high-speed injection molding, it must be right getting a start with mold design. CAD and CAE tools can be used to reduce gate position and cooling decisions. With proper molding design, less time is required for resin flow in the mold and better part quality is provided. Make sure to include ejector systems and runner formats that are oriented in a way to gain quick part evacuation and material flow.

Process Parameters

Mastering a list of parameters is the key condition of the process optimization in rapid injection molding. Set injection speed, pressure and back pressure for material type. PID temperature control monitors melt conditions to maintain stability and keep a closer eye on the switching points and high-speed machines for the sake of accuracy of the molding.

Cycle Time

Fast cycle time is the productivity enhancement option for the high-frequency molding. Effectively target cooling time goes down by using advanced cooling concepts and selecting appropriate types of materials. Reduce the injection and passing phases by correct adjustment of machine parameters. Such things as mold tool changes and part handling systems with automation reduce the variation in cycle times, which is a plus.

| Aspect | Material Selection | Mold Design | Process Parameters | Cycle Time |

| Key Focus | Material characteristics | Mold geometry & cooling system | Injection speed, pressure, temperature | Minimization |

| Considerations | MFI, thermal stability, resilience | Gate location, cooling channel design | PID control, V/P switchover, backpressure | Cooling, injection phases |

| Challenges | Warping, degradation | Ejection system design, mold wear | Balancing speed with quality | Reducing without affecting quality |

| Solutions | Use of hybrid materials, drying | CAD/CAE optimization, robust materials | Real-time monitoring, adaptive control | Advanced cooling techniques |

| Impact | Material flow, part strength | Cycle efficiency, part quality | Process stability, part consistency | Production throughput |

| Metrics | MFI rate, heat deflection temperature | Cooling time, ejection time | Injection pressure range, melt temperature range | Time per cycle, parts per hour |

Conclusion

The tech manufacturing industry in particular is now building on the new and high-speed injection molding standards introduced, which have set the criteria for fast and first quality. Performance of this method is high fruit of the use of advanced machines, accurate controls, and stringent tests so that each part gets produced in exacting standards.