In the ever-evolving world of innovation, a new term has begun surfacing in design labs, engineering circles, and materials science symposiums: Formula43. At first glance, it may sound like an experimental alloy or a line of racing tires, but its scope is broader, its implications deeper, and its name, like its applications, both deliberate and evolving.

Formula43 is not a product, not exactly a material, and certainly not a fleeting trend. It is a multidisciplinary performance standard—an evolving framework used to calibrate, measure, and optimize the performance of high-stakes systems, products, and processes. Think of it as a design principle rooted in mathematical efficiency, material resilience, and feedback-loop intelligence. Developed through years of iterative research and practical application, Formula43 has quietly but decisively become the benchmark behind the scenes of a range of modern technologies.

In this comprehensive article, we explore the origins, architecture, applications, and implications of Formula43, and examine how it is shaping the conversation around sustainable performance, smart design, and the balance between speed and longevity.

The Origins: Beyond the Blueprint

The seeds of Formula43 were planted at the intersection of high-performance motorsport engineering and computational materials research. Its earliest iterations were inspired by the need to reconcile two seemingly opposing demands: maximum power output with minimum material fatigue.

Early adopters in the aerospace sector experimented with hybrid materials and structural geometries that mimicked biological efficiency. Around 2018, a consortium of designers and materials scientists began formalizing a set of principles that could be repeated, validated, and scaled across disciplines. This collaborative model evolved into what is now referred to as Formula-43 Design Logic.

At its core, Formula43 is a systems optimization matrix. It combines stress-testing, environmental adaptation modeling, energy dispersion analytics, and long-term material integrity projections. But it does so with an elegance usually reserved for architecture or computational art.

Defining the Framework: What Exactly Is Formula43?

The beauty of Formula-43 lies in its modularity. It is both a formula and a philosophy, composed of five pillars:

- Structural Integrity Under Load

- Material Minimalism and Strength Ratio

- Thermal and Environmental Adaptivity

- Energy Feedback Loop Efficiency

- Digital-Physical Symbiosis

Each of these pillars has its own sub-metrics and evaluation criteria, many of which rely on AI-enhanced simulation or real-time field data.

A Formula43-approved design does not only meet performance benchmarks—it learns, adapts, and sustains. For instance, a Formula-43-driven drone isn’t just light and agile; it modifies its flight profile based on wind resistance over time, learns from route histories, and predicts battery decay rates down to the millisecond.

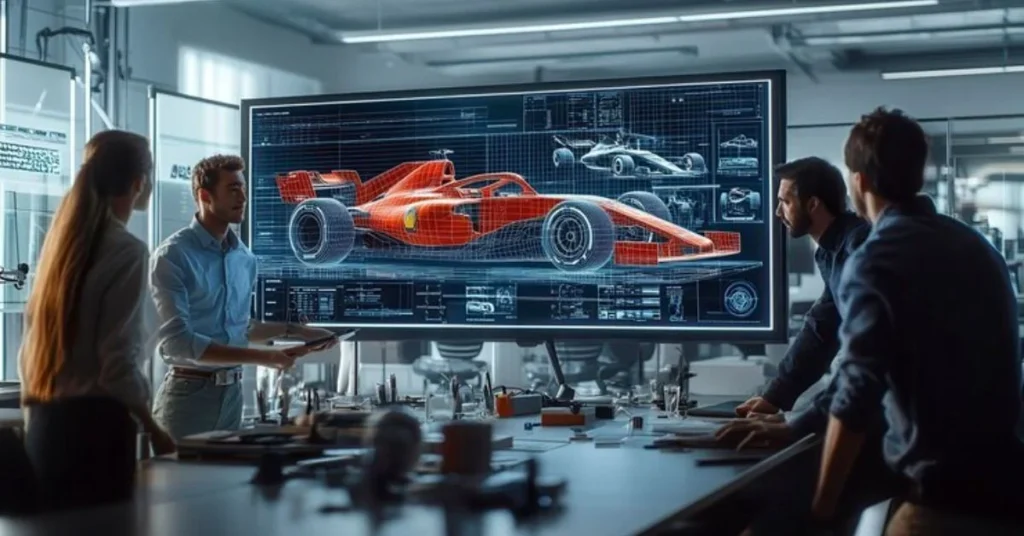

Use Case 1: Formula43 in Automotive Engineering

The most visible use of Formula-43 today is in high-performance electric vehicles. Battery weight, heat management, chassis stress—all are problem areas that traditional engineering models address in isolated terms. Formula43 reframes them as interdependent forces.

One breakthrough prototype, dubbed Project Iterra, utilized Formula-43 to reduce the chassis weight of an electric vehicle by 17%, while simultaneously improving crash resilience through lattice-geometry fusion techniques. The design was simulated 50,000 times before physical prototyping, with digital twins monitoring field data to suggest tweaks in real time.

In the words of the Iterra design lead, “Formula43 didn’t just help us optimize—it revealed options we didn’t even know we had.”

Use Case 2: Architecture and Urban Design

Formula43 principles are now being applied to climate-adaptive structures. A recent architectural study in Dubai deployed Formula43 to create façades that expand and contract based on heat and wind. Using minimal moving parts, the system redistributed thermal loads and reduced cooling costs by over 30%.

Here, Formula-43 isn’t about futuristic aesthetics—it’s about thermodynamic intelligence embedded in concrete, steel, and glass. The same metrics used to analyze turbine blades were repurposed to guide window placement and ventilation tunnels.

Use Case 3: Medical Device Design

In surgical robotics and prosthetic design, Formula43 provides the analytical backbone to reconcile the human body’s unpredictability with the machine’s need for repeatability. Designers use microdata from muscle contractions and bone density scans to adapt load-bearing joints and movement arcs in prosthetics.

In a clinical trial in Sweden, a Formula43-based prosthetic knee adapted dynamically to terrain changes, reducing patient fall risk by 44%.

The Materials Behind the Model

While Formula43 is not a specific material, its evolution has been deeply tied to advancements in meta-materials and phase-shifting alloys. The framework often recommends blends that alter their structural lattice in response to environmental stimuli.

These aren’t just reactive materials—they’re predictive substrates, designed to shift before damage occurs. The metrics for inclusion in Formula-43’s material database include not only tensile strength and conductivity, but also response latency and biological compatibility.

This has applications in wearable technology as well. Formula-43-compatible textiles can change porosity based on sweat composition or ambient humidity, opening possibilities in sportswear, tactical gear, and patient care.

The Role of AI and Predictive Modeling

One of the most powerful aspects of Formula43 is its dependence on AI modeling tools. These tools aren’t used post-design, but during every stage of ideation and iteration.

A Formula43 workflow typically includes:

- Generative design modules that test millions of shape variants

- Feedback simulations based on real-time sensor input

- Cross-domain scenario planning (e.g., combining traffic data with aerodynamic adjustments for vehicles)

The result is a closed-loop design environment, where every choice is evaluated not just for feasibility but for its long-term systemic harmony.

Formula43 in Aerospace and Space Design

As humanity extends its reach into orbit and beyond, Formula43 is finding a new frontier: zero-gravity material optimization. Structural designs for satellites and space modules are being recalibrated using Formula43 benchmarks.

NASA-adjacent labs are experimenting with Formula43-driven modules that can self-repair via embedded microfluidic channels—direct applications of the system’s emphasis on redundancy and feedback loops.

The challenge is formidable: materials must withstand thermal cycling between +120°C and –160°C, resist micrometeoroid impact, and minimize launch mass. Formula43 helps by offering a simulation platform that factors in the cumulative toll of orbital mechanics, solar radiation, and mechanical fatigue.

Open Source Philosophy and Community Collaboration

Formula43’s creators have opted for a semi-open model. While core algorithms and evaluation criteria are proprietary, the platform encourages community-driven adaptation.

A Git-based repository allows industrial partners to contribute test cases and validation data, while universities access Formula43-lite APIs for educational use. This has fostered a growing ecosystem of contributors from fields as diverse as biomechatronics, urban ecology, and renewable energy.

This model echoes the logic of Linux or CERN’s open science ethos—scalable, collaborative, and evolutionary.

Critiques and Controversies

Despite its acclaim, Formula43 is not without skeptics. Some critics argue that its complexity may inhibit widespread adoption in industries with tight margins and legacy systems.

Others question the ethics of AI-driven optimization when it comes to automated labor displacement, especially in manufacturing. If a Formula43 algorithm can design a drone in 48 hours that took a team of engineers three months, what happens to those jobs?

Still others raise privacy concerns around data collected during human-device interactions, especially in prosthetics and wearables.

These critiques are valid and necessary. Formula43’s creators have responded by emphasizing human-centric development, frequent audits, and ethical compliance protocols embedded into its AI modules.

What’s Next: The Roadmap of Formula43

Looking ahead, Formula43 aims to evolve in five strategic directions:

- Quantum Integration: Leveraging quantum computing for next-gen simulation speeds.

- Bio-Synthetic Interfaces: Materials that interface directly with neural or cellular systems.

- Decentralized Validation: Using blockchain for open verification of Formula43-compliant designs.

- Disaster-Responsive Architecture: Fast-deploying shelters that adapt to climate shocks.

- Cultural Engineering: Adapting Formula43 principles to non-technical domains like education design and crowd logistics.

Each of these directions signals a leap—not just in what we build, but in how we imagine systems, anticipate failure, and learn in real time.

Final Thoughts: More Than a Formula

Formula43 is not a product. It’s a principle for the post-industrial age, one that treats design as a dynamic, iterative, and morally complex act. Its rise is not marked by viral campaigns or mass-market slogans, but by its quiet infiltration into the frameworks we use to judge quality, efficiency, and resilience.

In a world facing intertwined crises—from climate change to supply chain breakdowns—Formula43 offers something rare: a language that engineers, designers, ethicists, and futurists can speak together.

And that, perhaps, is its most important contribution of all.

For more information, click here.