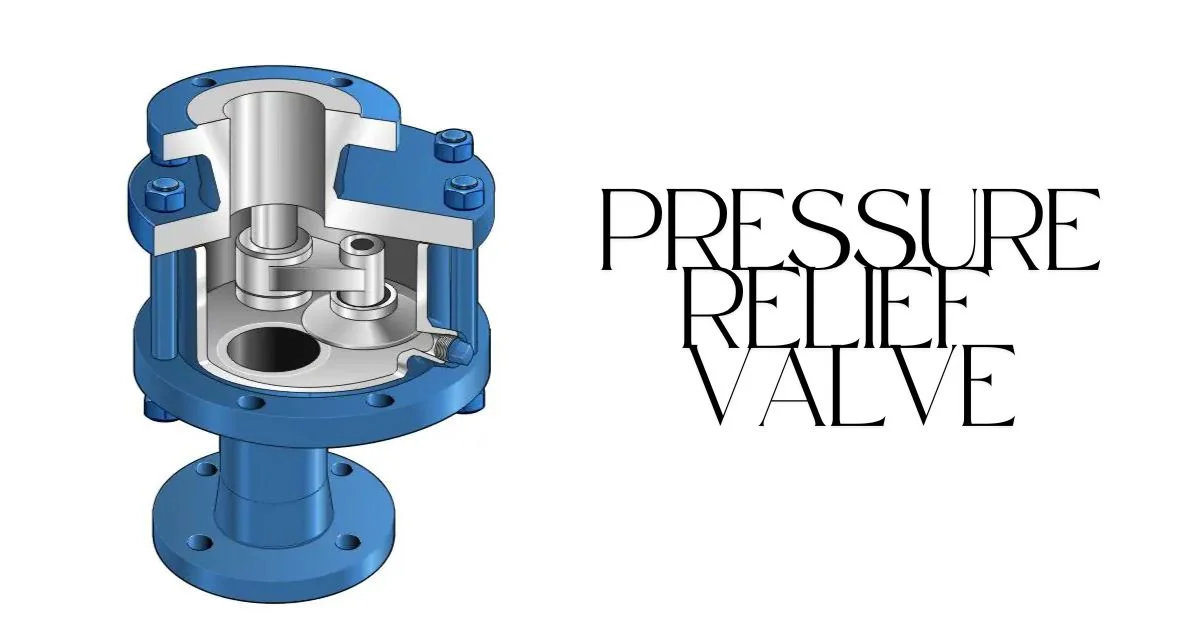

Different types of pressure relief valves keep our industrial equipment and systems safe from exploding. Also from getting damaged due to too much pressure. With the machinery, too much pressure without an escape route can lead to disasters. That’s where pressure relief valves step in.

Acting as a safety guard to release excess pressure. Now, let’s explore these cool types of these valves in a way that’s easy to understand and remember.

Safety Valves

Safety valves are the most common type of pressure relief valves. It’s designed to protect equipment and systems from overpressure. By releasing excess fluid or gas. These valves typically feature a spring-loaded mechanism that opens when the set pressure is reached.

This allows fluid or gas to escape until the pressure returns to normal levels. They are commonly found in steam boilers, pressure vessels, and pipelines.

Relief Valves

Relief valves share similarities with safety valves in function and design but operate with a more refined mechanism. Unlike traditional spring-loaded safety valves, relief valves utilize a pilot valve and diaphragm system, allowing for greater precision in managing pressure release.

These valves accommodate a wider range of operating pressures and can be meticulously adjusted to meet specific pressure demands. This versatility makes relief valves highly adaptable and suitable for diverse industrial applications.

Pilot-Operated Relief Valves

The pilot-operated valves are like having a smart assistant. They use a smaller valve (the pilot) to control the main valve. It’s a bit like using a small key to open a big door. This provides precise control over when to release pressure based on the conditions.

Pilot-operated relief valves are highly efficient and can handle high pressures. This makes them an excellent choice for large-scale industrial systems.

Process Valves

Process valves are crucial in managing how fluids flow through systems, directly influencing pressure control. These valves are the orchestrators in the industrial symphony. It guides the movement of liquids and gases.

By opening, closing, or partially obstructing pathways, they regulate flow rates and pressure. This ensures that systems operate smoothly and efficiently. Whether it’s by the twist of a manual handle or the signal to an automated actuator.

The process valves play a pivotal role in maintaining balance within complex industrial environments.

Temperature and Pressure (T&P) Relief Valves

Temperature and Pressure (T&P) relief valves are specialized safety valves commonly found in water heating systems. As the name suggests, they protect against excessive temperature and pressure build-up. By releasing excess water from the heater tank.

These valves function using a spring-loaded mechanism. This opens when the set temperature or pressure is reached. This also allows hot water to escape until the system returns to safe levels.

Learn More About the Different Types of Pressure Relief Valves Today!

Pressure relief valves are essential components in industrial equipment and systems. This ensures safe operation and prevents potential disasters. These types of pressure relief valves offer unique characteristics and functions. This makes them valuable in various industrial applications.

So, make sure to keep these in mind when it comes to managing pressure in your industrial operations. Next time you see a pressure relief valve, remember its critical role in maintaining stability and preventing disasters in the industrial world. It’s not just a simple valve, it’s a lifesaver!

Did you find this article helpful? Check out the rest of our blog!