Introduction

In the world of medical devices and equipment, custom PCB (Printed Circuit Board) design plays a crucial role in ensuring the reliability, safety, and functionality of these life-saving technologies. Custom circuit board design allows manufacturers to create electronics that are tailored to the specific needs of medical applications, taking into account factors such as size constraints, power requirements, and regulatory standards.

The Importance of Custom PCB Design in Medical Devices

Meeting Unique Requirements

Medical devices and equipment often have unique requirements that off-the-shelf PCBs cannot fulfil. Custom PCB design enables manufacturers to create boards that are optimised for the specific application, ensuring optimal performance and reliability.

Miniaturization and Integration

As medical devices become smaller and more complex, custom PCB design allows for the miniaturisation and integration of electronic components. This enables the development of compact, portable, and implantable devices that can improve patient care and quality of life.

Ensuring Safety and Reliability

In the medical industry, safety and reliability are paramount. Custom PCB design allows for the incorporation of redundant systems, fail-safe mechanisms, and other safety features to minimise the risk of device failure or malfunction.

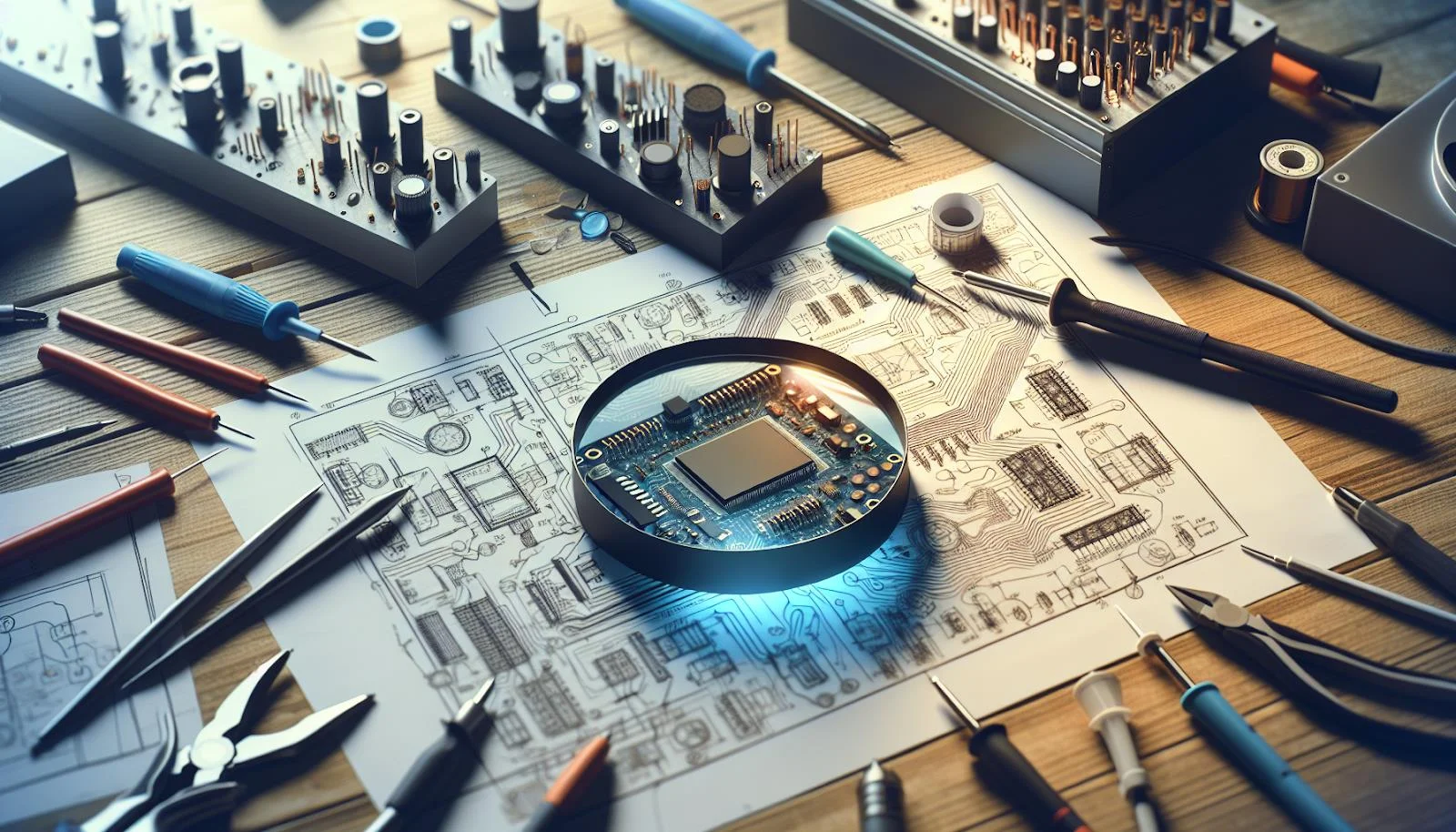

The Custom PCB Design Process

Understanding the Requirements

The first step in custom PCB design is to thoroughly understand the requirements of the medical device or equipment. This includes factors such as the intended use, operating environment, power requirements, and regulatory standards.

Schematic Design

Once the requirements are understood, the next step is to create a schematic design. This involves defining the electrical connections and components that will be used on the PCB. The schematic design serves as a blueprint for the physical layout of the board.

Component Selection

Selecting the right components is crucial for the performance and reliability of the PCB. In medical applications, components must be chosen based on their quality, durability, and ability to withstand the rigours of the intended use.

PCB Layout

The physical layout of the PCB is created based on the schematic design. This involves placing components, routing traces, and incorporating any necessary shielding or grounding. The layout must be optimised for signal integrity, power distribution, and thermal management.

Design Verification

Before the PCB is manufactured, the design must be thoroughly verified to ensure that it meets all the requirements and functions as intended. This involves simulations, testing, and design reviews to catch any potential issues or errors.

Considerations for Medical PCB Design

Regulatory Compliance

Medical devices and equipment are subject to strict regulatory standards to ensure patient safety. Custom PCB design must take into account relevant regulations such as ISO 13485, IEC 60601, and FDA guidelines. Compliance with these standards is essential for obtaining regulatory approval and bringing the device to market.

EMI/EMC

Electromagnetic Interference (EMI) and Electromagnetic Compatibility (EMC) are critical considerations in medical PCB design. Medical devices must be designed to minimise electromagnetic emissions and be immune to external interference. This involves proper shielding, grounding, and filtering techniques.

Signal Integrity

Maintaining signal integrity is crucial for the accurate and reliable operation of medical devices. Custom PCB design must take into account factors such as impedance matching, crosstalk, and signal reflections. Proper routing, termination, and shielding techniques are used to ensure signal integrity.

Power Management

Medical devices often have specific power requirements, such as low power consumption for battery-operated devices or the ability to handle high currents for certain applications. Custom PCB design must incorporate appropriate power management techniques, such as voltage regulation, power sequencing, and battery management.

Thermal Management

Heat generation is a common issue in electronic devices, and medical equipment is no exception. Custom PCB design must consider thermal management to ensure that components operate within their specified temperature ranges. This involves proper component placement, heat sinking, and the use of thermal interface materials.

Manufacturing Considerations

Material Selection

The choice of PCB material is important for the performance and reliability of the board. In medical applications, materials must be selected based on their electrical properties, thermal stability, and biocompatibility. Common materials include FR-4, polyimide, and ceramic substrates.

Surface Finish

The surface finish of the PCB plays a role in the solderability, durability, and reliability of the board. Common surface finishes for medical PCBs include ENIG (Electroless Nickel Immersion Gold), HASL (Hot Air Solder Levelling), and OSP (Organic Solderability Preservative).

Fabrication Techniques

Advanced fabrication techniques are often required for medical PCBs, such as high-density interconnect (HDI), microvias, and embedded components. These techniques allow for the miniaturisation and integration of complex electronics into small form factors.

Quality Control

Strict quality control measures must be in place throughout the manufacturing process to ensure the consistency and reliability of the PCBs. This includes inspections, testing, and traceability to ensure that each board meets the required specifications.

Testing and Validation

Functional Testing

Functional testing is conducted to verify that the PCB performs as intended and meets all the requirements. This involves testing the board under various operating conditions and scenarios to ensure proper functionality.

Environmental Testing

Medical devices and equipment must be able to withstand the environmental conditions they will be exposed to during use. Environmental testing, such as temperature cycling, humidity testing, and vibration testing, is conducted to ensure the reliability and durability of the PCB.

Accelerated Life Testing

Accelerated life testing is used to predict the long-term reliability of the PCB by subjecting it to elevated stress levels. This helps identify potential failure modes and ensures that the board will perform reliably over its intended lifetime.

Regulatory Testing

Depending on the specific medical application, additional regulatory testing may be required to demonstrate compliance with applicable standards. This can include electromagnetic compatibility (EMC) testing, electrical safety testing, and biocompatibility testing.

Collaboration and Communication

Design Team Collaboration

Effective collaboration among the design team is essential for the success of a custom PCB design project. This involves clear communication, regular design reviews, and the use of collaborative tools and software.

Supplier Collaboration

Close collaboration with suppliers is important to ensure the availability and quality of components, materials, and manufacturing services. Establishing strong relationships with reliable suppliers can help streamline the design and manufacturing process.

Customer Communication

Clear communication with the customer is crucial to ensure that the PCB design meets their specific needs and requirements. Regular updates, design reviews, and feedback loops help ensure that the project stays on track and meets the customer’s expectations.

Continuous Improvement

Design Optimization

Continuous improvement of the PCB design is important to enhance performance, reliability, and manufacturability. This involves analysing data from testing and field use to identify areas for optimization and implementing design changes as needed.

Process Improvement

Streamlining the design and manufacturing process can lead to faster development times, reduced costs, and improved quality. This involves identifying bottlenecks, implementing lean principles, and adopting best practices in PCB design and manufacturing.

Embracing New Technologies

Staying up-to-date with the latest technologies and trends in PCB design is important to remain competitive and meet the evolving needs of the medical industry. This includes adopting new materials, manufacturing techniques, and design tools as they become available.

Conclusion

Custom PCB design is a critical aspect of developing reliable, safe, and high-performance medical devices and equipment. By understanding the unique requirements of medical applications, following best practices in design and manufacturing, and collaborating effectively with stakeholders, companies can create custom circuit boards that meet the stringent demands of the medical industry.

As medical technology continues to advance, the role of custom PCB design in enabling new and innovative devices will only become more important. By staying at the forefront of electronics design and embracing continuous improvement, companies can position themselves to make a meaningful impact on patient care and quality of life.