3D printing with PLA filaments and PETG filaments offers different challenges and opportunities. Both materials are popular for various types of projects but require different techniques to optimize print quality. In this article, we’ll explore how to achieve successful prints with both materials by focusing on specific steps for each.

Printing with PLA Filaments

PLA filaments are among the most widely used materials for 3D printing, especially for beginners. Let’s go over the key factors that contribute to successful printing with PLA:

1: Preparing the Printer for PLA

Before starting any print with PLA filaments, it is essential to ensure that the printer is properly prepared. Cleaning the nozzle and making sure it’s free of old filament prevents clogging and ensures smooth extrusion. Skipping this step could lead to uneven prints or a complete print failure due to blockages.

2: Optimal PLA Printing Temperature

The optimal printing temperature for PLA filaments usually ranges between 180°C and 220°C. Printing within this range helps the material extrude evenly and bond layers effectively. It’s crucial to adjust the temperature based on the specific PLA brand you’re using, as different manufacturers may recommend different settings. Additionally, using a heated bed set to around 60°C can improve adhesion.

3: Bed Adhesion for PLA

While PLA Filament adhere well to most surfaces, improving bed adhesion is still important to avoid print lifting or warping. Using a glass bed, painter’s tape, or applying a thin layer of glue stick can help your print stick better. Good adhesion ensures that the print stays securely in place and doesn’t move during the process.

4: Print Speed for PLA

PLA filaments work best at moderate print speeds ranging from 40mm/s to 60mm/s. Printing too quickly may cause issues such as layer misalignment or poor surface quality. Slowing down the speed will allow each layer to cool properly before the next one is applied, resulting in a smoother and more accurate print.

5: Cooling Fans for PLA

Cooling plays a critical role in printing with PLA filaments. Once the first layer is down, setting the fan speed to 100% helps the filament solidify quickly, preventing warping and producing sharper details. Proper cooling is especially important when printing small, intricate objects, as it ensures high precision and a clean finish.

6: Retraction Settings for PLA

PLA filaments can sometimes cause stringing between objects, especially when the printer is moving between different parts of a print. Adjusting retraction settings by increasing the retraction distance and speed can help mitigate this problem. Fine-tuning these settings ensures cleaner prints with less post-processing.

7: Post-Processing PLA

Post-processing PLA filaments is relatively easy compared to other materials. PLA can be sanded, painted, or polished to improve its appearance. Additionally, PLA prints can be glued together for larger projects. Just be cautious with heat during post-processing as it can soften PLA, potentially warping or deforming your print.

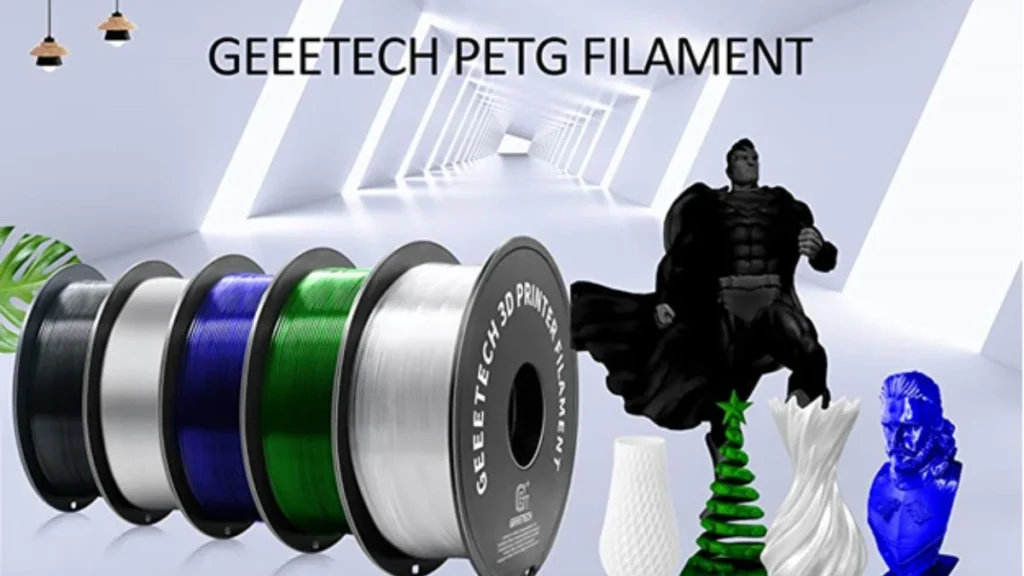

Printing with PETG Filaments

PETG filaments are known for their strength, flexibility, and durability. Let’s explore the best practices for achieving high-quality results when printing with PETG:

1: Preparing the Printer for PETG

As with PLA, it’s important to clean the nozzle before printing with petg filament. PETG tends to be more sticky than PLA, and any leftover residue can cause printing issues. A clean nozzle ensures that PETG flows smoothly during printing, reducing the chances of clogs or under-extrusion.

2: Optimal PETG Printing Temperature

PETG filaments require higher printing temperatures than PLA, typically between 230°C and 250°C. A heated bed set between 70°C and 90°C is also necessary to ensure proper bed adhesion. Printing PETG at the right temperature leads to stronger layer bonding, resulting in durable prints that can withstand stress and heat.

3: Bed Adhesion for PETG

One common issue with PETG filaments is that they adhere too well to the print bed, making the removal of prints challenging. Applying a thin layer of glue stick or using painter’s tape can prevent the filament from bonding too tightly to the surface, making it easier to remove the print without damaging either the bed or the object.

4: Print Speed for PETG

PETG filaments benefit from slower print speeds to ensure proper bonding between layers. Printing at speeds between 30mm/s and 50mm/s can produce better surface finishes and reduce common problems like stringing. Slower speeds also allow for better layer adhesion, creating stronger prints that are more resistant to impact.

5: Cooling Fans for PETG

Unlike PLA, PETG filaments don’t require as much cooling. It’s best to set the cooling fan speed to around 30-50%, especially for the first few layers. Too much cooling can weaken the layer bonding, resulting in cracks or poor structural integrity. Balancing fan speed is key to getting high-quality prints with PETG.

6: Retraction Settings for PETG

PETG filaments tend to produce more stringing due to their sticky nature. Adjusting retraction settings and slightly lowering the printing temperature can help minimize stringing between objects. Proper retraction settings are essential for maintaining clean and precise prints with PETG.

7: Post-Processing PETG

Post-processing PETG filaments can be slightly more challenging than PLA due to its flexible and durable nature. Sanding PETG can be tricky, but you can use a heat gun to polish and smooth the surface of your print. This process not only enhances the visual appeal of the print but also provides a professional finish.

Final Verdict

By following these best practices for PLA filaments and PETG filaments, you can optimize your 3D printing results. Each material has its unique properties and challenges, but by adjusting your printer settings and using the correct techniques, you can achieve high-quality prints with both. Whether you need PLA for ease of use or PETG for durability, mastering the art of printing with these filaments will expand your 3D printing capabilities.

If you found this article helpful, click here for more.